Wholesale Custom Wicker And Rattan Baskets: Tailored Solutions For B2b Traders

Dec 19, 2024 | Aarushi

Nagaland , a vibrant state in the northeastern region of India. Nestled amidst lush hills and valleys, Nagaland is home to diverse indigenous tribes, each with its own unique customs, languages, and art forms. The state is celebrated for its colorful festivals, traditional dances, and intricate handcrafts, which reflect the deep-rooted heritage of the Naga people. Kohima, the state capital, and Dimapur, the largest city, serve as cultural and economic hubs. Nagaland's natural beauty, combined with its cultural richness, makes it a captivating destination for those looking to explore India’s tribal heritage and scenic beauty.

Nagaland , a vibrant state in the northeastern region of India. Nestled amidst lush hills and valleys, Nagaland is home to diverse indigenous tribes, each with its own unique customs, languages, and art forms. The state is celebrated for its colorful festivals, traditional dances, and intricate handcrafts, which reflect the deep-rooted heritage of the Naga people. Kohima, the state capital, and Dimapur, the largest city, serve as cultural and economic hubs. Nagaland's natural beauty, combined with its cultural richness, makes it a captivating destination for those looking to explore India’s tribal heritage and scenic beauty. The diversity of people and ethnic groups, each with their own culture and heritage, creates a year-long atmosphere of celebrations. Living in a land where bamboo and cane are plentiful, the Nagas are expert bamboo weavers. So inextricably are the lives of the Naga with cane and bamboo that it is said, “In Nagaland, life starts in a cradle of bamboo and ends in a coffin of Bamboo”

(Image: Nagaland)

Beyond its forests rich in bamboo and cane, Nagaland has a rich cultural heritage and scintillating landscapes. There still lives a piece of culture in every Naga traditional home and with rich stories etched in every historical place, it is a paradise unexplored in every sense of the word. Nagaland is called the ‘Land of Festivals’, every tribal festival is celebrated with pomp and gaiety, adorned with rich and colorful traditional attires.

The most vibrant being the ‘Hornbill Festival’ where the songs of the ancient Nagas echo and its music reverberates in the true spirit of the tribal men. (Nagaland Tourism.)

Bamboo and Cane Culture of Nagaland

Nagaland is an important part of the colourful culture of India. The forests of Nagaland are rich in bamboo and cane. Thus, naturally they are expert basket makers. Basketry among the Nagas is highly developed. However, the craft is restricted to men. All Naga men know how to weave mats of split bamboo, which is the chief material besides wood for constructing walls and floors of houses. Very important is the production of finely woven mats for drying paddy.

(Image: Bamboo & Cane Culture of Nagaland)

Split bamboo is the usual material used for both mats and baskets. There are various stages involved in the preparation of baskets and other cane goods. It begins in the collection of raw materials from the forest, making splints of necessary sizes, weaving of the basket and finally giving the finishing touches. They now prepare different kinds of armchairs, sofas, tables and cradles for babies.

Apart from baskets, the Nagas make mats, shields and different kinds of hats from bamboo. They make attractive chungas or drinking cups; mugs made of bamboo with poker work. They are sometimes designed with painted stylized floral patterns or with human figures done in relief, greatly enhancing the shape and the texture of the articles.

Domestic Products

Bamboo Dish: A cheaper, lighter dish made of bamboo is seen in every house. A section of bamboo free of nodes is cut and shaved down until it is very thin. Then it is split down on one side and warmed over the fire, until it opens out flat. Two slits are then cut at each end and the ends are folded up like the ends of a paper parcel and laced in place with cane.

Bamboo Saucers: Bamboo saucers are used as appetizer dishes to hold the salted beans or hot chutney, which are eaten when drinking rice-beer.

Angami Naga Bamboo Spoons: The Angami Nagas, like several other hill tribes, use spoons of varying sizes shaped from bamboo. A bamboo culm of diameter 35 mm is shaped so that one nodal diaphragm is retained. A thick split extending from that node is shaped to form the handle and this split is bent slightly away from the axis of the culm for convenient handling. The lower part of the node and diaphragm are shaped by scraping with a dao, to create a soft rounded form.

(Bamboo Kitchen Accessories Set)

Kudzu: The Kedzu is a hayfork used by the Ao Nagas for shifting grass and hay. It is made of bamboo and has a very interesting form and structure. The handle is a length of whole culm bamboo and the fingers too are made from a bamboo culm.

Chang Bamboo Mugs: Among the Changs, who have an aesthetic sense more highly developed than their neighbours, the bamboo drinking mugs decorated with poker work designs called dobu thung- dobu means decorated, thung means mug- were originally made exclusively for the use of head takers. To burn the motifs on the body of the mug and the decorative pattern on the edge takes the maker at least three hours with short intervals while working. Since head-hunting has stopped, these decorative bamboo mugs are used only by rich men who can buy them, or anybody willing to exchange one for a basket of paddy weighing about 15 kg, or for labour. A maker of this kind of drinking mug may demand the tilling of a full field of paddy in exchange for one mug.

Weapons

Chang Naga Crossbow: The Chang Naga crossbow is a powerful weapon made of bamboo, wood, fibre and bone. It is made of a thick and strong bamboo beam, wider at the centre than the ends, held in a slot in the wooden cross-beam. The wooden cross-beam has a groove at the top on which the arrow rests. Towards the back of the cross-beam, a trigger assembly made of bone is used to hold the bow in tension as the bow-string made of fibre rope is held by the back of the trigger. The bow is held at arm length with both hands on the cross-beam holding it from below. When the trigger is pulled, the hook is depressed, permitting the bow-string to propel the arrow with great force. A good deal of strength is required to charge the bow as the bamboo beam is fairly thick and not easily bent.

3. Tribal Costume Accessories

Bamboo Combs: Small decorative combs of bamboo splits are made by Chang men as a gift to be given to girls.

Konyak Naga Belt: The Konyak Naga men wear a tight cane belt around their waists. These are made of half splits of cane wound around the waist in about seven or eight loops. The belt is worn by adults, and once it is put on, it is not removed until the man dies. The cane, due to constant contact with the body and body oils, becomes a beautiful golden yellow in colour.

Phipha: The Phipha is one of a pair of leggings worn by Angami and Ao Naga men of Nagaland. It is like a sleeve, open at both ends, with the top wider than the bottom and is worn over the calf to cover most of the leg between the knee and ankle. It is woven in a diagonal twill weave with very fine splits of cane. The lower portion, which has a slit along the side, is woven in natural coloured cane while the top portion-almost three-fifths of the length-is woven with splits of cane dyed a deep red colour. Bright yellow strips of orchid stem are used sparingly to make decorative patterns on the Phipha. Tufts of coloured wool are also used as decoration.

4. Fish Traps and Fish Baskets

Lithuo: This is a fishing tray used in Nagaland. It is made like a shallow square-based basket with the base woven in an open-twill weave, forming a net-like surface.

Ceremonial Headgear: The Ao Nagas use a decorative ceremonial hat, which is cone-shaped. It is made in two layers, the inner layer provides the structure and the outer layer is mainly decorative. The outer layer is made from dyed strips of bamboo or cane, and decorated with yellow and black stripes. The yellow strips may be bamboo or cane, but more often, they are the skin of an orchid stem, which turns bright yellow when dry. The red and black dyeing of bamboo and cane using natural dyes is the most significant aspect of these hats. The process of dyeing differs slightly from tribe to tribe.

(Indira Gandhi National Centre for the Arts)

Here are Some Bamboo and Cane Products from Rural Handmade Website

(Handmade Bamboo-Wood Ottoman)

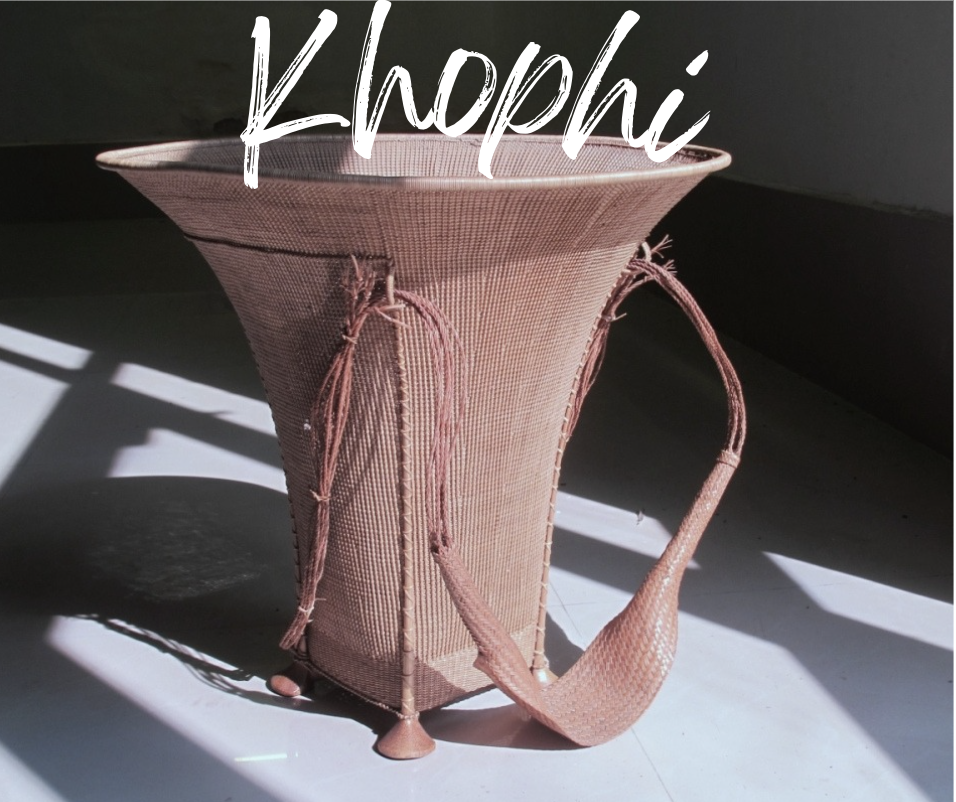

The Story of Khophi

The khophi is a traditional cane basket from the Angami Naga tribe of Nagaland, India. It's a utility basket that's used for carrying things, such as water and harvests from the fields. The khophi is known for its intricate designs and is a symbol of commitment in the tribe.The design and craftsmanship of the Khophi reflect the deep connection between the Naga people and their environment, as they used locally sourced bamboo, cane, and wood to craft these baskets. Over time, the Khophi became more than just a functional tool—it evolved into a symbol of the rich cultural heritage and the enduring craftsmanship of the Naga tribes. Today, while it continues to be used in everyday life, it is also cherished as a cultural artifact and a symbol of Naga identity and pride.

Origin:

A folk tribe tale states that once upon a time, there was a magician named Changkichanglangba who spent his life entertaining people with his tricks. Before he died, he told villagers to open his grave after six days of his burial. Following his instructions the villagers opened his grave and unearthed basketry designs and motifs. Smitten by the new designs, artisans started imitating those styles and basket making techniques.

The Nagaland forests are rich in bamboo and cane. Bamboo products hold a significant place in the lives of Nagas. It is believed that Naga tribes begin their lives in a cradle of bamboo and end their lives in a coffin of bamboo.

Traditionally, the basket craft was an age -old craft of leisure practised by the male elders. Family members indulged in this craft only to craft essential household items such as baskets, bamboo tubes, furniture, containers, spoons etc. Bamboo and cane crafts was limited to men. The Angami of Khonoma village in Kohima district craft Khophi, a carrying basket of cane that is presented by a man to his fiancée as a symbol of his commitment to her.

(Image: The Bamboo Bridge, Kohima)

Present Day: Every household of Nagaland is punctuated by this craft. It has penetrated into the architecture of the city such as in bridges and fencing bamboo and cane are the primary ingredients. This humble handicraft have won international accolades.

Since ancient times, the Angami tribe wears the crown of being the best in basket weaving. These baskets are available in varied designs, shapes and sizes. Even today, the constant companion of Naga womenfolk is a khophi basket.

The Khonoma village is famed for its intricate weaves and designs. The baskets of Khiamngan weavers in the Tuensang district are loved for their finesse and delicate work. (Craffi | Indian Handicrafts)

The Process of making Khophi

1. Splitting the Cane

Selection of cane: First, the craftsman carefully selects the cane for its flexibility, strength, and uniformity in color and texture.

Soaking the cane: The cane is soaked in water for several hours or even days to make it pliable, allowing for easier splitting and manipulation during the weaving process.

Vertical splitting: Using a sharp blade, the cane is split vertically. This requires precision to maintain uniformity in both width and thickness. The cane must be split in such a way that the strips have a smooth surface without any fraying or uneven edges.

Trimming the strips: After splitting, the edges of the cane strips are trimmed and sanded to remove any splinters or rough patches, ensuring that they can be woven smoothly without damaging the adjacent materials.

2. Weaving the Base

Laying out the cane strips: The strips are laid out in an intersecting grid pattern. For a square base, an equal number of strips are placed horizontally and vertically, ensuring that the spacing between each strip is uniform.

Starting the plain weave: A plain weave is achieved by alternately passing each horizontal strip over and under the vertical strips. This basic weaving technique forms a solid and strong foundation for the basket.

Tightening the weave: As each strip is woven, the craftsman tightens the intersections by pulling the strips carefully, ensuring there are no gaps or looseness that could compromise the base's integrity.

Securing the base: Once the square base is woven, the edges of the strips are secured to prevent them from loosening during the next stages of the process. This might involve tying, binding, or tucking the ends under the weave.

3. Adding the Warps

Placing on a mold: The woven base is placed on a mold that determines the shape of the basket (e.g., cylindrical or conical). The mold provides structure during the weaving process.

Turning up the warps: The vertical warp strips, which are initially part of the base, are turned upward around the mold. The distance between the vertical warps must be even for a uniform weave.

Inserting a continuous weft: A long strip of cane is used as the continuous weft. This strip is woven horizontally into the vertical warps, much like how the base was woven. The weft passes alternately over and under the vertical strips, slowly building up the height of the basket.

Securing each round: After each round of weaving, the craftsman tightens the weft to ensure that the basket's walls are sturdy and stable. Depending on the design, the weft may be woven tightly for a solid wall or more loosely for an open, airy pattern.

4. Adding Additional Warps (for Conical Baskets)

Measuring warp intervals: For conical baskets, additional warps are added as the basket narrows towards the top. The craftsman ensures that the distance between these new warp strips is uniform, as this ensures the basket's conical shape is symmetrical.

Inserting the additional warps: The additional strips are carefully inserted into the weaving pattern and aligned with the existing warps. These new warps are woven in the same manner as the original warps, seamlessly integrating into the overall structure.

5. Binding the Rim

Attaching a cane ring: A pre-shaped cane ring, often reinforced for added durability, is placed around the outer circumference of the basket’s top rim. This ring serves as a structural boundary for the rim.

Winding fine cane strips: Fine strips of cane are wound tightly around the cane ring, securing it to the basket. These strips are often applied with consistent tension to avoid gaps or looseness.

Trimming the ends: Once the binding is complete, the loose ends of the vertical warps are folded inward and tucked neatly under the weave. These ends are trimmed to prevent any rough edges from sticking out, giving the basket a clean and professional finish.

6. Attaching a Bamboo Frame

Preparing the bamboo frame: A frame made from bamboo is prepared to provide extra strength and durability to the basket. The bamboo is cut and shaped to match the basket’s size and structure.

Attaching the frame: The bamboo frame is securely fastened to the exterior of the basket. Typically, the frame includes vertical bamboo strips that align with the warps, providing additional rigidity.

Flaring the ends for legs: The ends of the bamboo strips are flared outward to form legs. These legs allow the basket to stand upright on its own. The legs must be evenly spaced and of uniform height to ensure stability.

7. Finishing

Sanding and cleaning: The entire basket is sanded to smooth out any rough areas, particularly around the edges and rim. The basket is then cleaned to remove any dust or debris from the weaving process.

Applying varnish: For special baskets or those intended for specific occasions, a coat of varnish may be applied to enhance the basket’s appearance and provide additional protection from wear and moisture. The varnish is applied evenly with a brush, ensuring that it penetrates all the crevices of the weave.

Drying: After the varnish is applied, the basket is left to dry in a controlled environment, ensuring that the finish cures evenly without smudging or uneven patches.

What are the Raw Materials and Tools Used?

Raw Materials used in Khophi Making:

Bamboo

Bamboo plays a vital structural role in Naga Khophi baskets, specifically used to form the legs of the basket. These legs are typically attached at the corners of the square base and provide stability, enabling the basket to stand upright. This unique feature is what gives the "khophi" its distinctive identity, as the word itself means "basket with legs." Bamboo is chosen for its exceptional strength-to-weight ratio, making it ideal for supporting the basket without adding unnecessary bulk. The bamboo used must be carefully selected, treated, and sometimes split into specific shapes to ensure uniformity in appearance and durability. When flared at the ends, the bamboo legs not only offer functionality but also add aesthetic balance to the overall design of the basket.

In traditional production, bamboo is harvested from local sources, where its natural abundance in the region makes it an environmentally sustainable material. Once cut, the bamboo undergoes curing processes to prevent decay, insect infestation, or warping. This treatment ensures that the legs of the basket maintain their structural integrity over time, even when subjected to frequent use or environmental conditions like humidity.

Cane

Cane is another critical material used in the construction of Naga Khophi baskets, particularly for reinforcing the rim. The rim serves as both a decorative and functional element that supports the overall shape of the basket. A cane ring, usually thicker and sturdier than the strips used for weaving, is attached to the outer edge of the basket's rim to provide reinforcement. This ring stabilizes the structure and ensures the basket maintains its form even under weight or pressure. After the cane ring is attached, fine cane strips are meticulously wound around it, securing the ring to the vertical warps, which creates a tight, durable finish.

Cane's flexibility and natural smoothness make it ideal for such detailed work. Before being used, the cane is often soaked in water to enhance its pliability, allowing it to be bent and woven without cracking. The fine strips are carefully selected to ensure they are uniform in size and texture, contributing to the basket's intricate and refined appearance. These strips are woven with great precision to ensure consistency, as even slight variations can affect the final product's look and function.

Tools used in Khophi Making

Dao (Long, Flat-Bladed Knife)

The dao is a traditional tool that has been integral to the basket-making process for generations. This long, flat-bladed knife is specially designed to split cane with great accuracy. Its flat, sharp edge allows the craftsman to make clean, straight cuts, which are essential when preparing the cane strips for weaving. The splitting process involves slicing the cane vertically, and the blade’s length ensures that the cuts are even along the entire strip, preventing any inconsistencies in the width or thickness of the material.

The dao requires skill to use, as it is crucial not to split the cane unevenly or too deeply, which could weaken the strip. Master craftsmen have developed precise techniques to control the pressure and direction of the cut, ensuring that the resulting cane strips are smooth and ready for further processing. The efficiency and versatility of the dao make it one of the most important tools in the basket-weaving process.

Die (Metal Plate with Holes)

The die is a metal plate fitted with various holes of different sizes, used to reduce the width of the cane strips to achieve uniformity. After the cane is initially split using the dao, the strips are passed through these holes in the die, which functions like a precision tool to trim the cane down to the desired width. This step ensures that all strips are of consistent size, which is crucial for achieving a balanced and even weave in the final product.

The die allows the craftsman to customize the size of the cane strips depending on the basket's design requirements. The tool’s efficiency also speeds up the process, as it removes the need for manual trimming and measuring of each individual strip. By standardizing the width of the cane strips, the die contributes to the high level of craftsmanship seen in Naga Khophi baskets, ensuring that every piece woven is symmetrical and well-proportioned.

Deer Horn (or Sharp Metal Rod)

Traditionally, deer horn was used to separate cane strips while weaving, though it has often been replaced by a sharp metal rod in modern times. The deer horn or metal rod is essential for pushing the weft or warp strips apart to make space for additional strips to be inserted during weaving. This tool helps the craftsman maintain the proper tension in the weave, ensuring that the pattern remains tight and consistent throughout the basket.

While the original deer horn tool added a cultural touch to the process, modern replacements such as sharp metal rods offer greater precision and durability. The rod is also versatile, as it can be used to adjust individual strips during the weaving process, tighten the weave, or correct minor mistakes. This tool allows for a fine degree of control over the weaving pattern, ensuring that the basket's structure is both aesthetically pleasing and functionally strong.

Knife

The knife is another indispensable tool in basket making, used primarily for splitting the cane into finer strips and for removing unwanted fibers from the cane’s surface. Unlike the dao, which is used for larger splits, the knife is more detailed and precise, allowing for closer work when trimming and refining the strips for weaving. It is also used to clean up the cane by shaving off rough edges, fibers, or imperfections that might affect the smoothness of the final product.

The skillful use of the knife ensures that the cane strips are perfectly prepared for weaving, with no stray fibers or uneven surfaces that could weaken the basket’s overall strength. Craftsmen often use the knife to fine-tune the materials throughout the production process, making sure that every strip of cane is flawless before it is incorporated into the basket. This attention to detail helps produce the high-quality finish that Naga Khophi baskets are known for.

(Image: Dao)

Market Survey of Khophi

1. Exceptional Quality of Khophi Handwoven Baksets

The exceptional quality of the Naga Khophi basket is one of its defining features, and a key selling point for both local and international markets. This quality stems from the use of high-grade bamboo and cane, materials known for their durability, flexibility, and resistance to environmental wear. Sourced locally, the bamboo and cane are carefully selected to ensure they are free of defects such as knots, cracks, or irregularities in texture. These materials are then treated to enhance their longevity, which is crucial given that Khophi baskets are often used to carry heavy loads in agricultural and rural settings. The treatment process may include drying, curing, and sometimes light polishing to protect the materials from rot, pests, and the effects of humidity.

The construction of a Khophi basket involves precise and skilled hand-weaving techniques, passed down through generations of artisans. The weaving process is done meticulously to ensure uniformity in the tension and pattern of the basket, which contributes to its overall strength. Unlike mass-produced baskets that are often machine-made and prone to inconsistencies, the handcrafted nature of Khophi baskets guarantees a higher standard of craftsmanship. Each basket is woven in a way that reinforces its structural integrity, making it capable of withstanding rough handling over extended periods. This level of detail ensures that every basket can endure the physical demands of carrying agricultural produce, household items, or other goods, making it a long-lasting tool for practical use.

For manufacturers looking to enter this business, understanding the importance of maintaining high standards in material selection and craftsmanship is essential. The durability and strength of the Khophi basket are its primary attributes, and any compromise in quality could affect its market reputation. Sourcing premium materials and ensuring that the artisans maintain their traditional weaving methods are crucial for upholding the product's quality. Additionally, manufacturers should consider implementing stringent quality control measures at every stage of production, from material sourcing to the final finishing. This will ensure that each basket meets consumer expectations for resilience and longevity, distinguishing it from cheaper, lower-quality alternatives.

2. Uniqueness of traditional Khophi design in Handwoven Baskets

The Khophi basket stands out in the marketplace due to its uniqueness and cultural significance, which are deeply rooted in the traditions of the Naga tribes of India. Each tribe within Nagaland has its own distinct style of basket weaving, and this regional diversity adds to the Khophi’s value as a handcrafted product. For example, some tribes favor square-shaped baskets, while others produce conical or cylindrical designs, each adapted to the tribe’s specific functional needs. This variety means that the design of each Khophi basket is highly unique, not just aesthetically but also in terms of its construction, giving it a diverse appeal to different market segments.

The designs themselves carry deep cultural meaning. Patterns and weaves often reflect the tribe’s history, beliefs, or social status, and the techniques used are passed down through generations, preserving the basket's authenticity. This makes the Khophi not just a utilitarian object, but also a symbol of cultural identity and heritage. For global consumers, especially in high-end or artisanal markets, this aspect of the Khophi’s design can be a significant draw. With increasing interest in products that tell a story, manufacturers have the opportunity to highlight the rich tradition behind the basket. By doing so, they can position the Khophi not only as a functional item but also as a piece of art that connects the buyer to the Naga tribes’ centuries-old weaving traditions.

Manufacturers entering this space should focus on preserving the authenticity of these traditional designs. While there may be a temptation to modernize or adapt the basket for broader markets, it is essential to retain the core elements that make each Khophi basket unique. This means ensuring that artisans continue to use traditional patterns, techniques, and materials. At the same time, manufacturers can explore ways to innovate within this framework, perhaps by introducing new sizes or color variations that appeal to contemporary tastes while staying true to the basket’s cultural roots.

In today’s global market, there is a rising demand for authentic, handcrafted goods that reflect cultural heritage. Products like the Khophi basket, which come with a strong narrative of craftsmanship and tradition, are particularly appealing to discerning customers who prioritize sustainability, originality, and cultural richness. Manufacturers can leverage this by marketing the Khophi not just as a basket but as a cultural artifact, thereby tapping into niche markets such as home decor, artisanal crafts, and cultural souvenirs.

3. Sustainable craftsmanship of Khophi

One of the most attractive aspects of the Khophi basket is its sustainability, which aligns with the growing global demand for environmentally friendly products. The Khophi is crafted primarily from bamboo and cane—materials that are not only abundant but also incredibly sustainable. Bamboo, in particular, is known for being one of the fastest-growing plants in the world, with some species capable of growing several feet in a single day. This rapid growth means that bamboo can be harvested without the risk of depletion, making it a renewable resource. Cane, too, is a sustainable material, often grown in a way that does not harm ecosystems. The harvesting of these materials does not involve deforestation, which further enhances their environmental credentials.

In addition to the sustainability of the raw materials, the production process itself is eco-friendly. Traditional basket weaving is a labor-intensive process that relies on manual skills rather than industrial machinery. This means that the carbon footprint of Khophi basket production is significantly lower than that of mass-produced, machine-made baskets. The use of hand tools and the absence of electricity-intensive processes ensure that the environmental impact is minimal. For manufacturers entering this business, this aspect of the Khophi basket is a major selling point, especially in markets where consumers are increasingly aware of and concerned about the environmental impact of their purchases.

Sustainability also extends to the longevity of the Khophi basket itself. Due to the durability of bamboo and cane, these baskets have a much longer lifespan than cheaper, synthetic alternatives. This makes them an environmentally responsible choice for consumers, as the need for frequent replacement is minimized. By offering a product that is both eco-friendly and long-lasting, manufacturers can appeal to a wide range of consumers, from environmentally conscious buyers to those seeking durable, practical solutions for everyday use. The fact that these baskets are biodegradable at the end of their life cycle further strengthens their appeal in the green marketplace.

For manufacturers, it is essential to highlight the eco-friendly nature of the Khophi basket in marketing and branding strategies. In today’s competitive market, where consumers are increasingly prioritizing sustainability, products that can demonstrate a commitment to environmental stewardship are more likely to succeed. Emphasizing the basket’s minimal ecological footprint—from the sourcing of materials to its handmade production and its long-lasting nature—will resonate with buyers who are looking to make environmentally responsible choices

(Image: Sustainability)

Green Manufacturing Initiatives

Bamboo is not only a fast-growing, renewable resource but also a highly efficient carbon sink. This means it absorbs more carbon dioxide (CO₂) than many other plants, making it an excellent material for environmentally sustainable products like the Khophi basket. Research indicates that bamboo can absorb up to 12 tons of CO₂ per hectare per year, which is significantly higher than the rate of carbon absorption by traditional hardwood trees. As a result, using bamboo in manufacturing Khophi baskets not only reduces the need for deforestation but also helps offset the carbon emissions produced in other parts of the supply chain.

For manufacturers, promoting bamboo’s carbon sequestration capabilities as a green initiative can strengthen their product’s appeal to environmentally conscious consumers. This can be done by ensuring that the bamboo used in production is sourced from sustainably managed bamboo plantations, where replanting and responsible harvesting practices are followed. By collaborating with bamboo suppliers who follow sustainable forestry practices, manufacturers can guarantee that their bamboo sources are continually replenished, ensuring the long-term sustainability of their materials. This approach not only enhances the environmental profile of the product but also supports the fight against climate change.

To implement this initiative effectively, Khophi basket manufacturers can adopt eco-certifications such as FSC (Forest Stewardship Council) or similar bamboo-specific certifications that verify the sustainable sourcing of their materials. Additionally, manufacturers can partner with environmental organizations to contribute to reforestation efforts in their local regions, further enhancing their role in carbon sequestration. Highlighting these initiatives in marketing materials will not only build brand loyalty among green consumers but also position the company as a leader in sustainable manufacturing.

Energy-Efficient Production: The traditional handweaving process used to create Khophi baskets is inherently energy-efficient. Unlike industrial production methods, which rely on heavy machinery that consumes vast amounts of electricity and other energy sources, traditional weaving requires little to no electricity. This significantly reduces the carbon footprint of Khophi basket production compared to energy-intensive industries like plastic basket manufacturing. Studies have shown that plastic production emits approximately 2.5 kg of CO₂ for every kilogram of plastic manufactured, whereas handweaving bamboo and cane into baskets has a near-zero energy cost.

Manufacturers can take further steps to ensure that their production processes remain energy-efficient. One approach is to maintain a manual or semi-automated production line that minimizes the use of electricity. Solar-powered lighting and equipment can be integrated where necessary to further reduce dependency on grid power. By utilizing renewable energy sources and prioritizing hand tools over power tools, Khophi basket makers can significantly lower their overall energy consumption, creating a greener production environment. This practice can be extended to the manufacturing facility’s infrastructure, using energy-efficient building materials, natural lighting, and ventilation to minimize energy use.

Furthermore, manufacturers can adopt low-impact production schedules, ensuring that production aligns with seasonal changes to optimize natural light usage and reduce artificial lighting needs. By offering training sessions for artisans on sustainable weaving practices and energy conservation, manufacturers can empower their workforce to contribute to reducing energy consumption. These efforts can be highlighted to potential clients, particularly in markets where consumers prioritize products made through energy-efficient and environmentally friendly processes.

Waste Reduction

Recyclability of Materials:The materials used in Khophi baskets—bamboo and cane—are completely biodegradable, offering a significant environmental advantage over synthetic alternatives such as plastic, which can take between 400 and 1,000 years to break down. When a Khophi basket reaches the end of its lifecycle, it naturally decomposes without leaving harmful residues or pollutants in the environment. This attribute makes Khophi baskets not only a sustainable choice but also a zero-waste product in terms of disposal. Unlike plastics, which contribute to landfills and oceans, Khophi baskets can return to the earth without causing long-term harm.

To maximize the benefits of material recyclability, manufacturers should promote closed-loop recycling systems within their production processes. This means any waste or leftover materials from the weaving process, such as bamboo and cane scraps, can be collected and either recycled or upcycled into new products. For example, smaller offcuts can be used in the creation of decorative items, smaller baskets, or even jewelry, providing an additional revenue stream while minimizing waste. Partnering with local artisans or other manufacturers to repurpose bamboo and cane scraps into paper, crafts, or furniture can further enhance sustainability by ensuring that no material goes to waste.

Manufacturers should also emphasize the reusability of worn-out Khophi baskets in their marketing, educating consumers on how these baskets can be repurposed into home decor, storage containers, or garden accessories. Encouraging consumers to find creative ways to extend the lifecycle of the baskets not only reduces environmental impact but also builds brand engagement, positioning the manufacturer as a leader in sustainable consumer goods.

Upcycling Possibilities: Beyond recyclability, Khophi baskets offer significant upcycling potential—an increasingly popular trend among eco-conscious consumers. When a Khophi basket becomes worn or damaged, it can easily be repurposed into a wide variety of functional or decorative items. For example, broken or old baskets can be transformed into smaller storage solutions, wall decor, or plant holders, extending their useful life while reducing waste. This upcycling approach provides an excellent opportunity for manufacturers to connect with environmentally conscious customers, offering suggestions and creative ideas for repurposing baskets once they have outlived their original purpose.

Incorporating upcycling workshops or tutorials into the company’s marketing strategy can create additional value for consumers and encourage long-term brand loyalty. Manufacturers can collaborate with artists or eco-designers to demonstrate how Khophi baskets can be reused in innovative ways, thus strengthening the product’s sustainability narrative. By fostering a community of customers who share tips and ideas on how to upcycle their baskets, manufacturers can create a strong, engaged customer base while further promoting the sustainability of their products.

Reduction of Carbon Emissions

Avoiding Industrial Production: One of the most significant advantages of Khophi basket production is its reliance on traditional, non-industrial methods. Avoiding energy-intensive industrial processes helps keep the carbon footprint of each basket significantly lower than that of mass-produced items. Industrial manufacturing, particularly in the plastic industry, is known to contribute between 20-30% of global carbon emissions, which comes from the heavy machinery, fossil fuels, and energy consumption involved. By sticking to manual craftsmanship, Khophi basket manufacturers can provide a low-carbon alternative to industrially produced goods, offering a product that is aligned with sustainable production principles.

Manufacturers can take this a step further by promoting green manufacturing practices throughout the entire supply chain. For example, bamboo cultivation methods can be improved by adopting agroforestry techniques, which integrate bamboo planting with other crops, improving soil health and increasing biodiversity. This approach helps reduce emissions while enhancing the environmental benefits of bamboo farming. Additionally, ensuring that the entire production process, from cultivation to final assembly, minimizes carbon emissions will further solidify the Khophi basket's status as a low-carbon, eco-friendly product.

Another step manufacturers can take is optimizing their distribution networks to reduce transportation-related carbon emissions. Localizing supply chains by sourcing materials and labor from nearby regions reduces the need for long-distance transportation, which is a significant contributor to carbon emissions. If Khophi baskets are sold primarily in local or regional markets, transportation-related carbon emissions can be drastically reduced. Furthermore, partnering with eco-friendly logistics providers or adopting green transportation methods, such as electric vehicles for local deliveries, will help minimize the product's environmental impact during distribution.

Transportation Emissions:Transportation is a major contributor to global greenhouse gas emissions, accounting for approximately 14% of all emissions. For manufacturers of Khophi baskets, minimizing transportation emissions is a key opportunity to further reduce the product’s overall carbon footprint. One of the most effective ways to achieve this is by emphasizing local sourcing and distribution. By producing and selling Khophi baskets locally, manufacturers can eliminate the need for long-distance shipping, which is often energy-intensive. Local markets not only reduce emissions but also foster a stronger connection with the community and offer faster, more sustainable distribution channels.

Manufacturers can also explore direct-to-consumer sales models to cut down on transportation and packaging waste. Selling Khophi baskets through online platforms or local retail outlets reduces the need for complex supply chains and bulk transportation, which often involves multiple modes of transport, increasing emissions at each stage. By consolidating distribution into more efficient, eco-friendly channels, manufacturers can significantly reduce their carbon footprint.

To further reduce transportation emissions, manufacturers could also adopt eco-friendly packaging and logistics solutions. Lightweight, biodegradable packaging can cut down on shipping weight, while partnering with green logistics providers who prioritize energy-efficient vehicles or carbon offset programs can ensure that the baskets reach their destination with minimal environmental impact. By incorporating sustainable practices throughout the supply chain, Khophi basket manufacturers can drastically lower their overall carbon emissions and appeal to a growing market of environmentally conscious consumers.

Market Size and Growth

Global Market for Handicrafts: According to a report by Grand View Research, the global handicrafts market was valued at USD 420.7 billion in 2021 and is projected to reach USD 732.1 billion by 2030, growing at a CAGR of 6.16% during the forecast period.

India's Handicrafts Market: India is a major player in the global handicrafts market, with a significant portion of its exports comprising traditional products like baskets.

Growing Demand for Sustainable Products: The increasing awareness of environmental issues has led to a surge in demand for sustainable products, including handicrafts.

Market Trends of Khophi

Market-Specific Use Cases for Wicker, Rattan, and Bamboo Baskets

Craft products like wicker, rattan, and bamboo baskets have versatile applications across international markets. As a wholesale buyer, understanding region-specific use cases can help position these products effectively for your target audience. This guide provides actionable insights into how these baskets can be marketed, along with real-world case studies and examples of successful use.

1. Eco-Friendly Home Decor

Market Appeal

United States: Eco-conscious consumers are drawn to natural, biodegradable materials for home aesthetics. Baskets serve as stylish storage solutions for living rooms, bedrooms, and bathrooms.

Canada: Popular for eco-friendly interiors with earthy tones and rustic designs.

Product Recommendations

Wicker baskets for organizing books, magazines, and throw blankets.

Bamboo baskets for displaying plants in indoor or outdoor spaces.

Marketing Tip

Highlight eco-certifications (e.g., FSC, Fair Trade) to appeal to environmentally conscious buyers. Use terms like "sustainable," "biodegradable," and "eco-friendly home essentials" for SEO optimization.

2. Rustic Storage Solutions

Market Appeal

United Kingdom: Small-space living drives demand for compact, versatile storage options. Woven baskets fit perfectly into shelves or under furniture for organized living.

Australia: Demand for outdoor storage solutions aligns with the country’s love for alfresco living.

Product Recommendations

Rectangular wicker baskets for kitchen pantries or bathroom shelves.

Durable rattan storage bins for outdoor use, treated with weather-resistant finishes.

Marketing Tip

Use social media platforms like Pinterest and Instagram to showcase creative storage ideas. Target hashtags like #RusticStorage, #HomeOrganization, and #EcoStorage.

3. Gifts in Eco-Conscious Packaging

Market Appeal

Germany: Known for its strong eco-conscious consumer base, buyers favor sustainable gifting options.

United States: Corporate gifting in eco-friendly packaging is a growing trend among businesses aiming to improve their green credentials.

Product Recommendations

Bamboo gift baskets for holiday hampers or corporate events.

Wicker trays wrapped in compostable film with branded ribbons for luxury gift packaging.

Marketing Tip

Offer customizable options for private labeling and branding. Emphasize terms like "eco-gifts," "corporate hampers," and "sustainable packaging solutions."

4. Luxury Retail Display and Packaging

Market Appeal

United States: High-end retail stores use handcrafted baskets for product displays in eco-conscious packaging.

Australia: Retailers in urban hubs utilize woven baskets to create visually appealing and sustainable displays.

Product Recommendations

Large rattan baskets for showcasing organic produce in grocery stores.

Decorative bamboo containers for high-end cosmetics or artisan goods.

Marketing Tip

Work with retailers to offer wholesale bulk orders tailored to retail use. Use visuals showcasing baskets in luxury retail spaces for marketing.

5. Hotel and Hospitality Use

Market Appeal

United Kingdom: Boutique hotels use handcrafted baskets for in-room laundry, toiletries, and mini-bar displays.

United States: Vacation rentals like Airbnbs use rustic baskets for functional decor and welcome kits.

Product Recommendations

Seagrass woven baskets for holding toiletries in bathrooms.

Wicker baskets for storing extra linens or as part of welcome kits.

Marketing Tip

Create bundles designed for hospitality buyers, including a mix of sizes and designs tailored to hotel or rental needs.

Case Studies: Successful Use in International Markets

United States: Eco-Friendly Retail Success

A major organic grocery chain introduced bamboo baskets as produce displays. This transition reduced plastic use by 30%, aligned with the store's sustainability goals, and increased customer satisfaction.United Kingdom: Boutique Hotel Partnership

A boutique hotel chain incorporated wicker baskets into their guest rooms, using them for laundry storage and mini-bar organization. This sustainable initiative received positive feedback, with customers noting the enhanced aesthetic appeal.Australia: Outdoor Living Solutions

An outdoor furniture retailer partnered with a rattan basket supplier to offer multipurpose storage options. These weather-resistant baskets quickly became a best-seller for patio and beach use.Canada: Corporate Gifting with a Green Focus

A corporate gifting company used bamboo hampers for holiday gifts. They offered customization options like logo embossing and compostable packaging, leading to a 20% increase in bulk orders.

Relevant Resources for Wholesale Buyers

Product Inspiration

Supplier Directories

Market Data

E-commerce Growth of Khophi: The rapid expansion of e-commerce platforms and online marketplaces provides Khophi basket manufacturers with global reach and direct-to-consumer sales opportunities. Establishing an online presence on platforms like Rural Handmade , Etsy, or Amazon Handmade enables manufacturers to showcase product authenticity, reach diverse consumer demographics, and facilitate international shipping. Optimizing digital marketing strategies and SEO tactics enhances online visibility and drives traffic to e-commerce storefronts.

Understanding market-specific use cases helps you position wicker, rattan, and bamboo baskets effectively in international markets. Whether for eco-conscious homes, luxury retail displays, or boutique hotels, these products offer versatility and appeal. Use the case studies and marketing tips above to maximize your success as a wholesale buyer.

For more personalized advice or access to trusted suppliers, explore the resources linked above and start optimizing your imports today!

Customizing Wicker, Rattan, and Woven Baskets for International Wholesale Markets

Market-Specific Customization Preferences

Each country has distinct consumer preferences influenced by trends, culture, and lifestyle needs. Here’s a breakdown:

United States

Design Trends: Rustic, boho-chic, and farmhouse-style baskets are highly popular for home decor. Consumers favor products with bold patterns or macrame-inspired weaves.

Functionality: Large wicker baskets for laundry, toy storage, and blanket organization dominate demand.

Customization Tip: Offer stackable, multi-purpose baskets with optional handles and liners.

United Kingdom

Design Trends: Minimalistic, neutral-colored baskets with soft tones like gray, beige, and white for Scandinavian-inspired decor.

Functionality: Compact, decorative baskets are preferred for small-space living and organizing pantry essentials.

Customization Tip: Focus on multi-pack sets for pantry organization or bathroom storage.

Canada

Design Trends: Eco-conscious buyers value sustainable, handwoven designs made from water hyacinth or seagrass. Earthy tones resonate strongly.

Functionality: Storage baskets for outdoor use, such as patio planters or picnic baskets, are in demand.

Customization Tip: Highlight biodegradable materials and cold-weather durability.

Australia

Design Trends: Coastal and tropical aesthetics with bright hues and natural textures appeal to Australian buyers.

Functionality: Lightweight baskets for beach storage and casual outdoor use are widely sought.

Customization Tip: Incorporate UV-resistant materials and bold, colorful designs for outdoor resilience.

Customization Costs of Handwoven Naga Baskets

Customization can add value to your products but also incurs additional costs. Here’s a breakdown of common customization services:

Design Customization Costs

Basic Changes (e.g., colors, size adjustments): $0.50–$2 per piece.

Complex Patterns or Embellishments: $2–$5 per piece, depending on the intricacy.

Private Labeling Costs

Logo Printing: $0.20–$0.50 per unit for basic logo embossing.

Custom Packaging: $1–$3 per unit for eco-friendly packaging options.

Material Customization Costs

Sustainable Materials (e.g., certified organic fibers): 10–20% higher material costs.

Special Finishes (e.g., water-resistant coating): $0.50–$1 per unit.

Volume Discounts

Most manufacturers offer tiered pricing, with discounts starting at 500+ units per design. Customization costs typically decrease as order quantities increase.

Sustainability Options: Meeting Market Demands

The growing demand for eco-friendly products makes customization in materials a priority:

Natural Fibers: Bamboo, seagrass, and water hyacinth for environmentally conscious buyers.

Non-Toxic Dyes: Ensure your products appeal to markets that prioritize health and sustainability.

Certifications: Look for FSC-certified wicker products to assure customers of sustainable sourcing.

Why Customization is Beneficial for Buyers

Higher Market Appeal

Tailored designs attract specific consumer demographics, increasing sales potential. For example, vibrant designs are more appealing in Australian markets, while neutral tones dominate in the UK.Brand Differentiation

Private labeling enhances your brand identity, giving you an edge in competitive markets. Branded packaging also ensures that your products stand out on retail shelves or online platforms.Sustainability Advantage

Offering eco-friendly options aligns with growing consumer demand for sustainable products, particularly in Canada and the US. Certifications like FSC or Fair Trade further boost consumer trust.Improved Profit Margins

Custom products often command premium pricing. For instance, a basic wicker basket might retail for $20, whereas a customized, branded version could fetch $35–$50.

Practical Considerations for Wholesale Buyers

Lead Times for Customized Orders

Standard Lead Time: 6–8 weeks, including production and shipping.

Rush Orders: Available for an additional fee, reducing production time to 3–4 weeks.

Prototyping and Quality Assurance

Request physical or digital prototypes to ensure the final product matches your specifications. Prototyping costs range from $100–$200 per design.Compliance with Import Regulations

Customized products must meet the labeling and safety standards of your target market. For example:US: Compliance with FTC labeling requirements.

Canada: Bilingual (English/French) labels for retail products.

Customizing for Specific Uses

Retail Products

Offer compact, stackable sets with attractive packaging. Example: Multi-pack woven storage baskets for pantry or bathroom use.Corporate Gifting

Incorporate elegant branding options like laser-etched logos or branded ribbons for gift sets.Outdoor Applications

Use UV-resistant or water-repellent finishes for markets like Australia, where outdoor storage is popular.

How to Get Started with Custom Orders

Partner with Reliable Suppliers: Vet suppliers who specialize in handmade crafts with positive reviews and compliance certifications.

Define Your Requirements: Specify designs, dimensions, and materials during the initial discussion.

Communicate Clearly with Manufacturers: Share detailed design briefs, including sketches or mood boards.

Verify Costs and Timelines: Ensure your budget aligns with the quoted costs and lead times.

Request Samples: Approve prototypes before proceeding with full production.

Plan for Logistics: Coordinate shipping, customs clearance, and local distribution early to avoid delays.

Carbon Emissions in Production of Khophi Basket

Carbon Sequestration by Bamboo and Cane

The primary raw materials for Khophi baskets are bamboo and cane, which play an essential role in carbon sequestration during their growth cycle.

Bamboo Carbon Sequestration: Bamboo is a highly efficient carbon sink. It can sequester carbon at a rate of 1.5 metric tons of CO₂ per hectare per year, depending on the species and growing conditions .

On average, a hectare of bamboo plantation can absorb 62-68 metric tons of CO₂ over a 40-year growth period .

Cane Carbon Sequestration: Similar to bamboo, rattan cane is also carbon positive. A study by the International Network for Bamboo and Rattan (INBAR) shows that rattan sequesters approximately 0.2 metric tons of CO₂ per hectare per year .

For artisanal production, using locally sourced bamboo or rattan helps offset emissions through this natural carbon capture.

Artisanal Khophi Basket Production: Minimal Carbon Emissions

In traditional, small-scale basket weaving, emissions are negligible due to the absence of electricity, minimal use of fuel, and biodegradable materials.

Energy Consumption: Artisanal production mostly relies on manual labor. In a typical village setting, no significant energy-consuming equipment is used. Estimates suggest that the carbon footprint of handcrafting a Khophi basket is close to zero, particularly when renewable materials like bamboo are involved.

If we assume zero machinery is used, the only emissions involved come from human activities such as transportation (i.e., walking or cycling to gather materials).

Transportation Emissions (Local):

For small-scale artisans, raw materials are generally sourced locally, often within 10-20 km of the artisan’s location. A single basket requires around 2-4 kg of bamboo or cane .

Assuming a person uses a bicycle or similar low-emission transport, the carbon footprint is approximately 0.016 kg of CO₂ per km . Over a 20 km round trip, this results in emissions of 0.32 kg of CO₂ per basket, if transportation is the only emission-generating activity.

Mass Production of Khophi Baskets: Escalating Carbon Emissions

Scaling the production of Khophi baskets introduces machinery and global distribution, which increases carbon emissions significantly. Here are potential sources of carbon emissions for a mass production scenario:

Industrial Manufacturing:

If machinery such as industrial cutters or power looms is introduced, electricity consumption spikes. On average, a single industrial loom consumes approximately 1.5 kWh per hour .

Assuming an industrial setting where 20 baskets per hour are produced, the electricity consumption would be around 0.075 kWh per basket.

If the energy comes from non-renewable sources (such as coal), the carbon intensity is 0.475 kg CO₂ per kWh . This means the carbon footprint for manufacturing one Khophi basket would be around 0.036 kg of CO₂.

Transportation Emissions (Global):

If Khophi baskets are mass-produced for export, transportation will become a major contributor to the carbon footprint. For example, shipping from a factory in India to Europe or North America could result in significant emissions:

Sea freight emits about 0.02 kg of CO₂ per ton-km .

For a 10,000 km journey by sea, shipping 1 ton of baskets (approximately 500 baskets per ton) would generate around 200 kg of CO₂, or 0.4 kg of CO₂ per basket.

Air freight, by comparison, emits significantly more—about 2.2 kg of CO₂ per ton-km . For a 10,000 km journey, this results in 4.4 kg of CO₂ per basket, making it much less sustainable than sea freight.

Life Cycle of Khophi Baskets

One of the environmental benefits of Khophi baskets is their biodegradable nature. However, understanding the decomposition process is key:

Biodegradation of Bamboo and Cane: In natural conditions, untreated bamboo and cane will decompose within 6 months to 3 years, depending on the environment .

During decomposition, bamboo and cane release CO₂ back into the atmosphere. However, the overall net emissions remain relatively low due to the material’s prior carbon sequestration.

Total Carbon Footprint

Artisanal Khophi Basket Carbon Footprint:

Raw material collection: 0.32 kg of CO₂

Production: Negligible (assumed near-zero energy use)

Transportation: Local, low-emission

Total carbon footprint per artisanal basket: Approximately 0.32 kg of CO₂

Mass-Produced Khophi Basket Carbon Footprint:

Raw material transportation: 0.4-0.8 kg of CO₂ (long-distance transport)

Production: 0.036 kg of CO₂ (industrial processes)

Global distribution (sea freight): 0.4 kg of CO₂ (sea freight) or 4.4 kg (air freight)

Total carbon footprint per mass-produced basket:

With sea freight: Approximately 0.836 kg of CO₂ per basket

With air freight: Approximately 4.836 kg of CO₂ per basket

Carbon Reduction Techniques

To mitigate the increased carbon footprint from scaling Khophi basket production, several strategies could be implemented:

Renewable Energy Sources: By powering factories with solar or wind energy, the production emissions of 0.036 kg of CO₂ could be cut to zero.

Efficient Transportation: Using sea freight instead of air freight would reduce emissions by over 90%, significantly lowering the carbon footprint.

Sustainable Forestry: Ensuring bamboo and cane are sourced from well-managed, renewable plantations would maintain carbon sequestration benefits.

(Image: Basket Weaving)

(Image: Handmade Bamboo & Cane Basket)

(Image: Outdoor Cane Chair)

(Image: Cane Made Open Fruit Bowls)

(Image: Cane Charger Plates)

(Image: Bamboo Storage Basket)

Wholesale Pricing of Handwoven Baskets and Minimum Order Quantity (MOQ)

As a wholesale buyer looking to import wicker, rattan, or bamboo craft products, understanding wholesale pricing structures and MOQ requirements is crucial. This guide offers a detailed overview of pricing tiers, MOQ expectations, bulk discounts, and flexible pricing models, tailored to help you make informed purchasing decisions.

1. Wholesale Pricing Tiers - Understanding Cost Structures

Pricing for wholesale craft products varies based on factors such as order volume, material quality, customization, and production complexity. Here’s how pricing tiers typically work:

Volume-Based Pricing

Small Orders (50–100 units): Higher cost per unit due to setup fees and production inefficiencies.

Example: $10–$15 per basket for a standard woven design.Mid-Sized Orders (200–500 units): Moderate discounts due to economies of scale.

Example: $8–$12 per basket.Large Orders (1,000+ units): Significant price reductions, especially for repeat buyers.

Example: $5–$8 per basket.Material-Based Pricing

Basic Materials (e.g., bamboo, seagrass): $5–$10 per unit for standard designs.

Premium Materials (e.g., FSC-certified rattan, dyed wicker): $10–$20 per unit.

Customization Costs

Adding logos, unique patterns, or custom sizes can increase costs by 10–30%.

For example, a standard basket may cost $7, while a customized version with private labeling could cost $9–$10.

2. Minimum Order Quantity (MOQ): What Wholesale Buyers Should Know

MOQ is the smallest quantity a manufacturer will produce in a single order. It’s set to cover production costs and ensure profitability.

Standard MOQs for Craft Products

Basic Products (non-customized): 100–500 units.

Customized Products: 200–1,000 units, depending on the complexity.

Why MOQs Matter

Production Costs: Craft products often involve manual labor, so small orders may not justify production setup costs.

Raw Material Sourcing: Manufacturers typically purchase materials in bulk, influencing MOQs.

Negotiating Lower MOQs

Pay a Premium: Offer a higher price per unit for smaller batches.

Partner with Other Buyers: Share an order with another buyer to meet MOQ requirements.

Trial Orders: Request a one-time lower MOQ as a trial run for future larger orders.

3. Bulk Discounts and Flexible Pricing Models

Bulk Discount Structures

Discounts are typically tiered based on order volume:

5–10% off for 500–1,000 units.

15–20% off for 1,000+ units.

25%+ off for 5,000+ units.

Recurring Buyer Incentives

Many suppliers offer loyalty discounts for regular customers, such as:

First-Time Buyer Discount: 5–10% off the initial order.

Repeat Orders: 5% off for subsequent orders over 500 units.

Annual Contracts: Locked-in lower rates for recurring purchases.

Flexible Pricing Models

Freight-Inclusive Pricing: Bundles product costs with shipping for transparent total costs.

FOB (Free on Board): Pricing covers costs until the goods are shipped, excluding freight charges.

CIF (Cost, Insurance, Freight): Pricing includes freight and insurance up to the buyer’s port.

4. Factors Influencing Wholesale Pricing

Several variables impact wholesale prices:

Raw Material Costs

Fluctuations in bamboo or rattan prices due to seasonal availability.

Labor Costs

Manual weaving processes increase costs compared to automated production.

Customization and Branding

Logos, patterns, and unique sizes add labor and material expenses.

Shipping and Logistics

Bulk shipments by sea are cheaper than air freight but take longer.

5. Real-World Examples: Pricing for Popular Craft Products

Wicker Storage Baskets

Basic Design (500 units): $6 per basket.

Customized with Logo (500 units): $7.50 per basket.

Rattan Laundry Baskets

Standard Size (1,000 units): $8 per basket.

Eco-Friendly FSC-Certified Material (1,000 units): $10 per basket.

Bamboo Gift Sets

Simple Gift Set (200 units): $15 per set.

Premium Packaging and Branding (200 units): $18 per set.

6. Tips for Wholesale Buyers

Request Detailed Quotes

Always ask for a breakdown of costs, including raw materials, labor, customization, and shipping.

Use Cost Estimation Tools

Tools like Freightos can help estimate shipping costs for bulk orders.

Understand Supplier Capabilities

Choose suppliers experienced in handling large orders with consistent quality.

7. Resources for Wholesale Buyers

Alibaba Supplier Directory: Find manufacturers offering competitive pricing and MOQs.

Trade Tariff Tools: Calculate import duties for your target market (UK Trade Tariff).

Eco-Certified Suppliers: Check FSC Marketplace for certified manufacturers.

Rural Handmade : E-commerce Supply Chain Marketplace with a network of 5000+ Artisanal Communitites

Conclusion: Maximize Value with Strategic Buying

Understanding wholesale pricing and MOQ requirements is vital for securing the best deals and ensuring profitable imports. By leveraging bulk discounts, negotiating flexible pricing, and choosing the right suppliers, wholesale buyers can maximize value while meeting market demands.

For personalized advice or to explore trusted suppliers, check out the resources provided above and start optimizing your wholesale craft product imports today!

Cost Reduction Techniques for Khophi

For manufacturers entering the Khophi basket market, one of the key challenges is finding cost reduction techniques that do not compromise the product’s quality or cultural authenticity. While the production process is inherently labor-intensive and artisanal, there are still strategies to streamline operations and reduce unnecessary costs. Below are a few critical cost-reduction approaches:

Bulk Sourcing of Raw Materials: As bamboo and cane are the primary raw materials, bulk purchasing from reliable suppliers can significantly lower material costs. Partnering with bamboo and cane suppliers to secure long-term contracts could provide volume discounts of up to 10-20%. Additionally, opting for local sourcing within Nagaland or nearby areas reduces transportation and logistical expenses. Manufacturers could also explore options for cultivating their own bamboo and cane, further lowering costs over the long term, although this would require upfront investment.

Training and Upskilling Artisans: Increasing productivity without compromising quality can help lower labor costs over time. By providing artisans with proper training and tools, manufacturers can increase efficiency in the weaving process. For example, training artisans to handle multiple weaving techniques simultaneously or investing in semi-mechanized tools for splitting cane can reduce the time required to produce each basket. This increased efficiency could result in a 20-30% reduction in labor costs per basket while maintaining the artisanal touch.

Production Scaling: Scaling production by expanding the artisan base or establishing multiple workshops can reduce overhead costs per unit. As the number of baskets produced increases, the fixed costs (such as rent and utilities) are distributed across a larger volume of goods, reducing the per-basket cost. Additionally, creating a centralized distribution hub could minimize transportation costs by ensuring that raw materials and finished products are efficiently managed from one location.

Leveraging E-commerce Platforms: By reducing reliance on traditional retail channels and using direct-to-consumer e-commerce platforms, manufacturers can cut down on middleman fees and marketing expenses. Online marketplaces specializing in artisanal or eco-friendly products often charge lower fees than brick-and-mortar stores, enabling manufacturers to maintain competitive pricing while increasing their profit margins.

Economies of Scale

Profit Margin vs. Selling Price

Balancing Quality and Cost of Khophi Baskets

For a new manufacturer entering the Khophi basket business, the key to long-term success is balancing quality and cost to meet consumer expectations without overshooting production expenses. Khophi baskets have a reputation for high-quality craftsmanship, and any compromise in quality could negatively impact the brand’s reputation and demand. Therefore, ensuring that cost reduction techniques do not affect the basket's durability, aesthetic, or cultural authenticity is crucial.

Quality of Raw Materials: While purchasing bamboo and cane in bulk can lower costs, manufacturers must be cautious not to compromise on the quality of the materials. Lower-quality bamboo may be cheaper, but it could be prone to splitting, weakening the structural integrity of the baskets. To maintain the durability and flexibility of the Khophi basket, only high-quality bamboo and cane should be used, even if it means slightly higher material costs. This decision would ultimately pay off in customer satisfaction and lower product returns.

Preserving Traditional Craftsmanship: As the Khophi basket is deeply rooted in the cultural heritage of Nagaland, maintaining the authenticity of traditional weaving techniques is essential. While some cost-saving methods (like semi-mechanization) can be applied to less skilled tasks such as preparing materials, the actual weaving should remain handcrafted. This not only justifies the higher price point but also ensures that the cultural value and uniqueness of each basket are preserved. In a market where consumers increasingly value authentic, handmade goods, compromising on craftsmanship to cut costs could be counterproductive.

Quality Control Systems: Implementing rigorous quality control systems is critical for balancing cost and quality. Each basket should be carefully inspected at multiple stages of production to identify any potential issues with weaving, material strength, or finishing. Manufacturers can introduce standardized guidelines for artisans to follow, ensuring consistency in quality without sacrificing efficiency. By identifying and addressing any quality issues early in the production process, manufacturers can avoid costly reworks or product returns, thus maintaining high-quality standards while keeping production costs in check.

Product Differentiation: Another effective strategy for balancing quality and cost is through product differentiation. Manufacturers can offer multiple versions of the Khophi basket—such as basic, mid-tier, and premium models—each catering to different segments of the market. While the basic models might use simpler designs and standard materials, the premium versions could feature intricate weaves, special finishing techniques, or personalized elements that justify a higher price point. By creating tiered pricing models, manufacturers can appeal to both budget-conscious consumers and those willing to pay more for exclusivity, thereby maximizing revenue without compromising overall quality.

Production Time vs Labour Costs

Maximizing ROI and Profitability fOR Importing Khophi Baskets and Other Handwoven Crafts

Understanding the return on investment (ROI) and profitability for various buyer personas is crucial when considering importing handwoven crafts like Khophi baskets. Below, we detail how each persona can benefit financially, along with key strategies to maximize their investment.

1. Eco-Conscious Retailers

How Importing Khophi Baskets Drives ROI

High Demand for Sustainable Products: Eco-conscious consumers are willing to pay a premium for environmentally friendly and handmade products. Studies show that 68% of global consumers prefer buying products with a clear sustainability narrative.

Profit Margins: Retailers can mark up prices by 100–150%, with retail prices for baskets ranging from $25 to $100, depending on size and design.

Brand Differentiation: Selling Khophi baskets aligns with sustainability goals, enhancing brand loyalty and attracting new customers.

Strategies for Profitability

Promote Certifications: Highlight eco-certifications like FSC or Fair Trade to justify premium pricing.

Exclusive Collections: Develop seasonal or exclusive product lines to attract repeat customers.

Cross-Selling Opportunities: Pair baskets with complementary eco-friendly items like reusable bags or organic candles.

2. Corporate Gift Suppliers

How Importing Khophi Baskets Drives ROI

Corporate Gifting Trends: Businesses increasingly prioritize sustainable gifting, with 78% opting for eco-friendly options for corporate events or holidays.

Profit Margins: Bulk pricing allows suppliers to purchase baskets for $8–$12 per unit and sell as part of a $50–$100 gift package.

Reputation Enhancement: Offering handcrafted, ethical gifts strengthens relationships with corporate clients and builds credibility.

Strategies for Profitability

Custom Branding: Offer private labeling or branded baskets for corporate clients, increasing perceived value.

Seasonal Demand: Target holidays like Christmas or Earth Day with pre-designed gift bundles.

Long-Term Contracts: Secure contracts with corporations for recurring orders to stabilize revenue.

3. E-Commerce Sellers

How Importing Khophi Baskets Drives ROI

High Online Demand: Platforms like Etsy and Amazon report significant sales growth for artisanal products. A single well-marketed listing can generate up to $2,000 monthly revenue.

Profit Margins: Import costs of $8–$15 per basket can be marked up to $30–$80, depending on design and target audience.

Global Reach: E-commerce allows sellers to target niche markets globally, ensuring consistent sales.

Strategies for Profitability

SEO-Optimized Listings: Use keywords like “sustainable handwoven baskets” or “eco-friendly storage solutions” to rank higher in search results.

Customer Reviews: Encourage satisfied buyers to leave reviews to boost credibility and attract more customers.

Bundled Offers: Increase average order value by bundling baskets with related items like home decor products.

4. Hospitality and Event Planners

How Importing Khophi Baskets Drives ROI

Cost-Effective Decor: Bulk imports of handwoven baskets can save up to 30% compared to renting or purchasing high-end decor locally.

Upselling Opportunity: Hotels and event planners can incorporate baskets into premium packages, charging clients for unique, sustainable aesthetics.

Long-Term Savings: Durable, reusable baskets reduce the need for frequent replacements, lowering overall costs.

Strategies for Profitability

Customized Offerings: Provide tailored basket designs for specific themes or events, increasing exclusivity and value.

Partnership Deals: Collaborate with boutique hotels or luxury event planners for repeat bulk orders.

Marketing as Sustainability Champions: Position the baskets as eco-friendly decor options to align with growing client demands for green practices.

5. Wholesalers and Distributors

How Importing Khophi Baskets Drives ROI

High Bulk Margins: Distributors can import baskets at $5–$10 per unit and sell them to retailers or e-commerce sellers at a 50–100% markup.

Market Expansion: Serving diverse markets, including retail chains, gift shops, and online platforms, maximizes revenue potential.

Scalability: The growing global demand for handmade crafts ensures consistent opportunities for scaling operations.

Strategies for Profitability

Diverse Product Range: Stock multiple basket designs to cater to varied client needs, from rustic storage to luxury decor.

Streamlined Logistics: Partner with reliable shipping and warehousing providers to reduce costs and enhance efficiency.

Exclusive Contracts: Secure agreements with artisan cooperatives for exclusive designs, boosting demand from premium buyers.

6. Interior Designers and Decor Studios

How Importing Khophi Baskets Drives ROI

Luxury Market Appeal: Handwoven baskets appeal to high-end clientele, with designers marking up prices by 200–300%.

Versatile Applications: Baskets are used for decor, storage, and functional art pieces, increasing their usability across projects.

Repeat Business: Delivering unique and sustainable designs ensures loyalty from clients and recommendations for new projects.

Strategies for Profitability

Bespoke Designs: Collaborate with artisans for custom-made baskets tailored to project themes.

Showroom Displays: Showcase the baskets in design studios to attract walk-in clients.

Sustainability Marketing: Position baskets as eco-friendly luxury decor to justify premium pricing.

7. Social Enterprises and NGOs

How Importing Khophi Baskets Drives ROI

Mission Alignment: Supporting artisan communities aligns with social impact goals, attracting funding and partnerships.

Ethical Branding: NGOs and social enterprises can market baskets as symbols of cultural preservation and sustainability.

Revenue Generation: Selling baskets at craft fairs or online platforms ensures steady income for community programs.

Strategies for Profitability

Storytelling Marketing: Share artisan stories to add emotional value and attract socially conscious buyers.

Corporate Partnerships: Partner with businesses for CSR-driven bulk orders.

Membership Models: Offer exclusive access to limited-edition baskets for donors or supporters.

8. Boutique Store Owners

How Importing Khophi Baskets Drives ROI

High Perceived Value: Customers shopping at boutique stores are willing to pay a premium for unique, handcrafted items.

Low Competition: Offering niche, exclusive products reduces direct competition with mass-market retailers.

Seasonal Sales Boosts: Limited-edition collections for holidays or events can drive spikes in revenue.

Strategies for Profitability

Small MOQs: Work with artisans or suppliers offering small MOQs to manage inventory costs.

Local Marketing: Leverage community events and social media to promote the baskets as local, artisanal finds.

Exclusive Collaborations: Partner with artisans to create custom designs exclusive to the store.

Key Takeaways