Crafting Sustainable Futures: Integrating Traditional Handmade Techniques Into Modern Creative Manufacturing

Jan 18, 2024 | Muskan Jangra

In a world where tradition meets innovation, sustainability, and manufacturing go hand in hand. Here, we'll explore the amazing concept of integrating traditional handmade techniques into modern creative manufacturing. In a world where everyone is running towards innovation and efficiency, stress emerges between tradition and modernity, sustainability and manufacturing. The persistence of progress in the manufacturing sector has undoubtedly brought numerous advantages, but at what cost? Harming the environment or losing traditional values.

In a world where tradition meets innovation, sustainability, and manufacturing go hand in hand. Here, we'll explore the amazing concept of integrating traditional handmade techniques into modern creative manufacturing. In a world where everyone is running towards innovation and efficiency, stress emerges between tradition and modernity, sustainability and manufacturing. The persistence of progress in the manufacturing sector has undoubtedly brought numerous advantages, but at what cost? Harming the environment or losing traditional values. This blog delves into the possibilities where the integration of traditional handmade techniques into modern creative manufacturing not only bridges this gap but also promises a sustainable future. That helps to save our traditional practices along with new technologies. A combination of technology and handmade provides results that bring a change into the developing world and help to cover the SDG goals.

As the world witnesses the rise of modern manufacturing, the advantages are apparent. Precision, efficiency, and scalability have become synonymous with contemporary production processes. Every coin has two sides; however, the flip side reveals a dark truth – high resource consumption, pollution, and a staggering amount of waste generation. The environmental footprint of these practices is a growing concern that cannot be ignored. The rise of technology raises concerns about how we are going to save the natural environment and how to maintain a carbon footprint during the production process.

The purpose of this blog is to analyze this emerging trend, exploring how the integration of traditional handmade techniques into modern manufacturing can lead to a more sustainable and ethical business model. By examining the environmental impact of modern manufacturing, the enduring value of traditional techniques, and the innovative ways to bridge the gap between the two, we can gain a deeper understanding of the potential benefits and challenges inherent in this integration.

1. The Rise of Modern Manufacturing and its Environmental Impact

Modern manufacturing has significantly revolutionized the way products are designed, produced, and distributed. It offers numerous advantages with its precision, efficiency, and scalability that transform our world, enabling mass production to meet the demands of a global market. However, this revolution has not come without costs. But as we embrace these advancements, we must also acknowledge the environmental impact they bring.

High resource consumption, pollution, and waste generation have become urgent concerns that demand our attention. The heavy toll on our natural resources, the significant environmental pollution, and the mounting waste challenge our responsibility towards the planet. The flip side of this progress is the high resource consumption, pollution, and waste generation that have contributed to environmental degradation and climate change.

Increase in demand for Industrial Revolution 5.0 that may accomplish eco-friendly products and help to maintain the connectivity of industry and sustainable material. It may bridge a gap between Capitalism & Sustainability. Currently, Industry raises the number of carbon footprints, ecological imbalance, and a major impact on human life. With growing concerns about the ecological footprint of current manufacturing practices, there is a pressing need for more sustainable alternatives. Although, currently these sustainable majors are also a concern. The connection between naturally friendly products or substances with industry is increasing day by day. Industrialists are also raising their concerns about using sustainable materials and handmade practices. Addressing these environmental concerns requires a shift towards more sustainable and eco-friendly manufacturing practices, including the integration of traditional handmade techniques and the adoption of green technologies.

2. The Enduring Value of Traditional Techniques

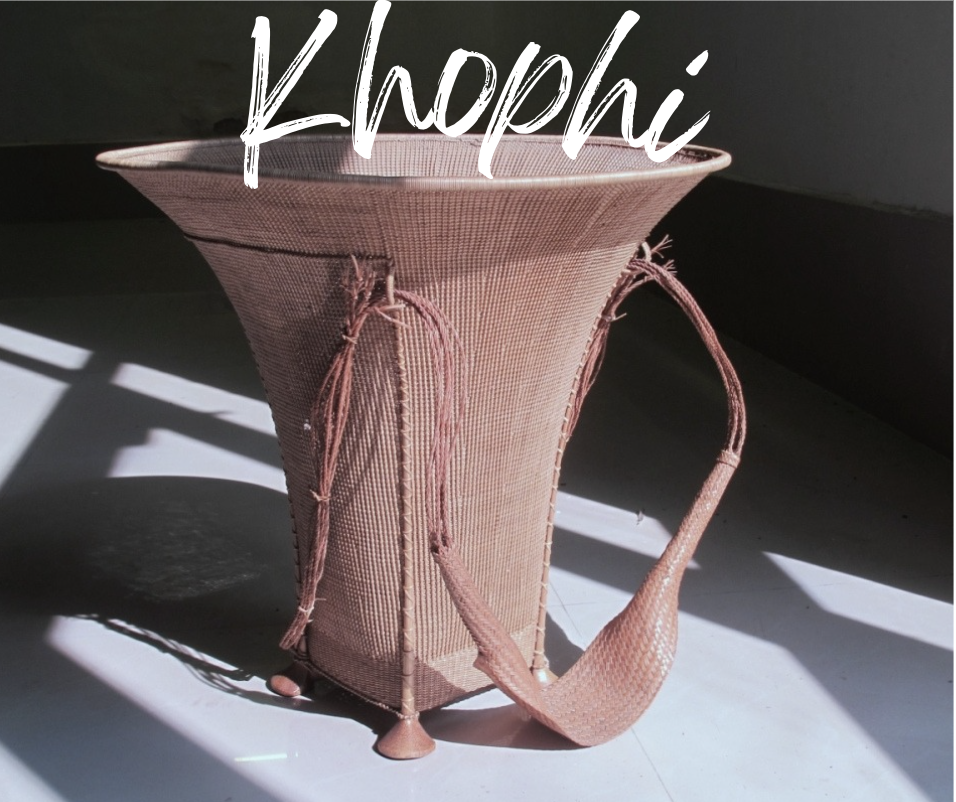

Now, let's shift our focus to the timeless charm of traditional handmade techniques. These age-old practices have been passed down through generations, embodying sustainability at their core. Contrasting modern manufacturing, traditional handmade techniques have stood the test of time, embodying the essence of sustainability. These techniques rely on locally sourced materials, embrace low-tech processes, and generate minimal waste. From intricate weaving and pottery to wood carving and embroidery, traditional crafts from different cultures exemplify the harmony between human creativity and nature, fostering artisanal skills that have been passed down through generations. Imagine a craftsman in a small workshop, using locally sourced materials and age-old methods that produce minimal waste. These practices, steeped in history and culture, from the intricate woodwork of Bali to the vibrant textile weaving of Ghana, offer lessons in sustainability that are more relevant today than ever.

Take, for example, the intricate art of handloom weaving. From India's vibrant Banarasi silk to Peru's richly patterned textiles, traditional handloom weaving showcases the beauty of sustainable craftsmanship. These techniques not only preserve cultural heritage but also ensure a minimal ecological footprint. Also, it helps to connect with Sustainable Development Goals for a progressive connection with the environment.

3. Bridging the Gap: Integration and Innovation:

Now, let's explore how modern technology and design can bridge the gap between tradition and innovation. By embracing these tools, we can adapt and enhance traditional techniques, making them even more sustainable and efficient. It is the key to unlocking the potential of integrating traditional techniques into modern manufacturing lies in innovation and adaptation. By leveraging modern technology and design, traditional crafts can be both preserved and enhanced.

Imagine artisans using 3D printing technology to create molds for pottery, combining the beauty of handmade craftsmanship with the precision of modern manufacturing, and modern material science can be applied to enhance the durability of traditional materials, ensuring longevity and quality. Additionally, digital platforms can be built to promote and scale up traditional crafts, connecting artisans with global markets and creating new opportunities for sustainable businesses. Or envision the integration of solar-powered machinery into traditional woodworking, reducing reliance on fossil fuels and minimizing environmental impact.

By embracing innovation while honoring tradition, we unlock a world of possibilities for sustainable creative manufacturing. Through collaboration and knowledge sharing, we can pave the way towards a greener future.

The Benefits of a Sustainable Future

The integration of traditional techniques into modern manufacturing offers a wide range of benefits. This brings manifold benefits. It's about reducing our environmental footprint, yes, but it's also about preserving cultural heritage, supporting artisan communities, and creating products with a unique story and soul. This approach not only meets environmental goals but also adds value to products in a way that resonates with consumers seeking authenticity and meaning. By significantly reducing the environmental impact of production processes, businesses can contribute to conservation efforts and promote eco-friendly practices. Furthermore, this integration supports cultural preservation, reviving artisan communities and preserving their unique skills and knowledge. The products that result from this fusion are not only high-quality but also carry a rich narrative, providing consumers with a deeper connection and appreciation for the items they purchase. Economic benefits include empowering local economies and promoting fair trade, leading to a more equitable and ethical marketplace.

The integration of traditional handmade techniques with modern manufacturing methods offers a promising pathway toward a more sustainable and culturally rich future. This fusion not only addresses environmental concerns but also brings a multitude of socio-economic benefits. Let's explore these positive outcomes in detail:

Handicrafts rely on natural, locally sourced materials, promoting a lower carbon footprint compared to the mass-produced, synthetic materials commonly used in modern manufacturing. Handmade methods typically require less energy, reducing overall consumption and greenhouse gas emissions also recyclable. When combined with modern energy-efficient technologies, the environmental impact can be minimized further. Traditional crafting often involves the use of materials with minimal waste. When these principles are applied in modern manufacturing, it results in more efficient use of resources and reduced waste production.

Cultural Preservation and Revival of Artisan Communities:

By integrating traditional techniques, the rich cultural heritage embedded in these crafts is preserved. This not only keeps the history and stories alive but also ensures that age-old skills are not lost to time. It can bring renewed interest and demand for traditional crafts, providing artisans with a sustainable livelihood. It helps in keeping the communities vibrant and economically viable.

Creation of Unique, High-Quality Products with a Story:

Products that blend traditional craftsmanship with modern design stand out in a market saturated with uniform, mass-produced items. They offer a unique aesthetic and quality that is highly valued by discerning consumers. These products carry stories of cultural heritage, skill, and the fusion of old and new. This narrative aspect can create emotional connections with consumers, adding intangible value to the physical product.

Empowering Local Economies and Promoting Fair Trade:

Sourcing materials locally and involving artisan communities in production, this approach can stimulate local economies, creating jobs and supporting small businesses. Integrating traditional techniques often involves a commitment to fair trade principles. This ensures that artisans are paid fairly and work under ethical conditions, promoting social equity.

In a market where consumers are increasingly conscious about the environmental and social impact of their purchases, products that are sustainably made and support local communities have a competitive edge. Modern manufacturing and marketing methods can help traditional crafts reach a wider, global audience, increasing sales and recognition for artisan products.

Challenges and Opportunities

While the potential benefits of integrating traditional techniques are substantial, some challenges need to be addressed. These include access to resources, cultural barriers, and limitations in scalability. One of the primary challenges in blending traditional techniques with modern manufacturing is the limited access to necessary resources. Traditional crafts often rely on specific, locally sourced materials that may not be readily available or sustainable on a larger scale. Additionally, modern technocrats manufacturing technologies and expertise can be out of reach for small-scale artisans.

Here are a few major challenges/barriers faced by craftsmen to blend traditional techniques with modern Technology:

Limited Resources: Traditional crafts often require specific, locally sourced materials which can be hard to obtain in large quantities. Also, artisans might lack access to modern tools and technologies that could enhance their craft.

Cultural Acceptance: There can be a significant cultural divide between traditional artisans and modern manufacturers. This includes differences in language, values, and working methods. There's also the risk of cultural appropriation or misunderstanding the significance of certain traditional techniques.

Scalability: Traditional methods are typically labor-intensive and time-consuming, making it difficult to scale up production without losing the essence of the craft. This poses a challenge in meeting the demands of a global market where quick production turnaround is often a priority.

Opportunity:

Collaborative Initiatives: Engaging both artisans and modern manufacturers for collaboration can lead to innovative products that are both culturally authentic and scalable. For instance, artisans can share their unique skills and knowledge, while manufacturers provide access to better resources and new markets.

Educational Programs: Implementing educational initiatives for both artisans and manufacturers can bridge cultural gaps and enhance mutual understanding. For artisans, training in modern business practices, sustainability, and technology can expand their capabilities. Similarly, educating manufacturers about the value and techniques of traditional crafts can foster greater appreciation and integration of these practices.

Policy Changes: Government and industrial bodies can facilitate this integration through supportive policies which may include financial incentives for businesses that incorporate traditional techniques, grants for artisans to access modern equipment, and laws to protect the intellectual property of traditional crafts.

Adaptation for Technology: Using modern technology to complement rather than replace traditional techniques can help to scale up production while maintaining authenticity.

Sustainable Resource: Creating sustainable resources for traditional materials can ensure a steady supply without depleting natural resources.

By addressing these challenges with thoughtful strategies and collaborative efforts, the integration of traditional craftsmanship and modern manufacturing presents significant opportunities. It not only preserves cultural heritage but also opens new measures for sustainable, scalable, and innovative production.

Conclusion

The fusion of traditional handmade techniques with modern creative manufacturing holds incredible promise for crafting sustainable futures. As we navigate the challenges of a rapidly changing world, let's not forget the wisdom and beauty of the past. By integrating tradition and innovation, we can build a future where sustainability and manufacturing thrive hand in hand.

In conclusion, integrating traditional handmade techniques into modern creative manufacturing not only presents an opportunity to build a more sustainable future but also offers a way to honor and preserve traditional crafts and skills. By embracing this fusion and supporting businesses that prioritize sustainability and cultural preservation, we can collectively influence a positive change in the business landscape. I encourage B2B readers to explore and support sustainable practices that integrate traditional techniques, thereby contributing to a more ethical and vibrant marketplace.

Recommended