A Complete Guide To Ajrakh And The Process Of Ajrakh Making

Jul 23, 2024 | Shagun Sneha

Craft, in essence, refers to the skill and practice of creating items by hand. These creations generally carry cultural significance, blending tradition with artistry to produce arts that are both functional and decorative. Crafts encompass a wide range of techniques and materials, from pottery and weaving to metalwork and textile arts, each reflecting the heritage and creativity of its makers.

Craft, in essence, refers to the skill and practice of creating items by hand. These creations generally carry cultural significance, blending tradition with artistry to produce arts that are both functional and decorative. Crafts encompass a wide range of techniques and materials, from pottery and weaving to metalwork and textile arts, each reflecting the heritage and creativity of its makers. Ajrakh is a distinguished form of hand block printing on cotton fabric, along with a rich history that spans over 4,500 years in India. This ancient craft has been propelled to its current prominence through technological innovations that have intricate geometric patterns from ancient urban ruins. Ajrakh stands as a cultural emblem, signifying personal and familial identity. The authenticity and value of Ajrakh lie in its origins, creation process, colors, and designs. The meticulous hand block printing involves the use of natural dyes like indigo and madder, as well as printed mordants. Each piece of Ajrakh is a testament to the artisanal skills and cultural heritage, making it a treasured craft both in India and beyond.

Ajrakh - a distinguished form of hand block printing.

HISTORY

Approximately twenty-five centuries ago, before the time of Buddha, there was significant trade between the Babylonian Empire and the Indian subcontinent. This period marked the beginning of the widespread exchange of goods, ideas, and cultures. Merchants, often adorned in blue cloth with intricate embroidered work, traveled along trade routes, bringing with them the art and techniques of textile making.

Historical records indicate that these merchants were instrumental in spreading the craft of Ajrakh. The use of indigo and madder dyes in Ajrakh printing gave the fabric a distinctive appearance that was highly sought after in ancient markets. Lassen, a notable historian, has asserted that even Egyptian mummies were wrapped in muslin cloth originating from India. This suggests that Indian textiles, including those employing techniques similar to Ajrakh, were highly valued across different cultures and regions. The presence of Indian muslin in Egypt highlights the extensive reach and influence of Indian textile craftsmanship in ancient times.

Ajrakh has evolved significantly over the centuries. Initially, it was practiced primarily by the Khatri community in the Kutch region of Gujarat and the Sindh region of Pakistan. These artisans perfected the art of hand block printing, using wooden blocks to imprint designs onto fabric. The process involved multiple stages of dyeing and printing, each layer adding depth and intricacy to the final piece.

The discovery of advanced geometric patterns in the excavated ancient cities further refined the craft. These patterns, now synonymous with Ajrakh, have been preserved and passed down through generations, ensuring that the essence of this ancient art form remains intact.

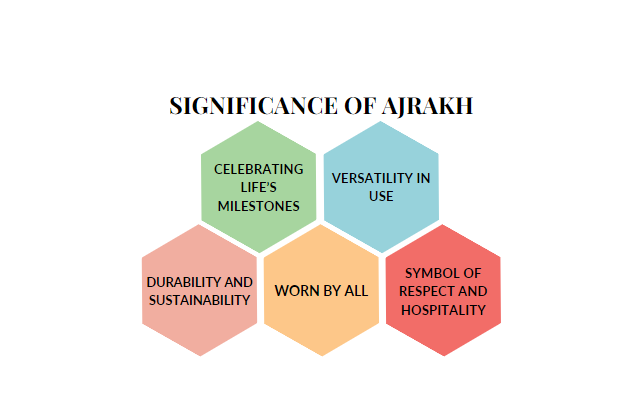

WHAT IS THE SIGNIFICANCE OF AJRAKH?

Ajrakh holds deep cultural and social significance in the regions where it is practiced, particularly in Gujarat, India, and Sindh, Pakistan. This intricate textile art is a vital part of the community's cultural identity, marking various significant events and daily practices throughout the life cycle.

Celebrating Life's Milestones

From birth to marriage, Ajrakh fabric plays a prominent role in celebrating and honoring life's significant milestones. The vibrant and intricate patterns of Ajrakh are often used in ceremonies and rituals, symbolizing good fortune and prosperity. For instance:

Birth: Ajrakh is used to swaddle newborns, believed to offer protection and blessings.

Marriage: During weddings, Ajrakh fabrics are used as part of the bridal trousseau, signifying tradition and continuity.

Versatility in Use

Ajrakh fabric is versatile and is used in various forms, making it a staple in daily life as well as special occasions. It can be worn and utilized in multiple ways:

Turban: Men often wear Ajrakh as turbans, which signifies respect and honor.

Shawl: Ajrakh shawls are popular for their warmth and aesthetic appeal.

Bedsheet: The fabric is used as bedsheets, adding a traditional touch to home decor.

Durability and Sustainability

Ajrakh is known for its durability and is often reused until it becomes threadbare. This practice not only highlights the fabric's resilience but also underscores a sustainable approach to textile use. The lifecycle of an Ajrakh piece, from a new garment to a well-worn relic, reflects its enduring value and the sustainable practices of the communities that cherish it.

Worn by All

Ajrakh transcends social and economic boundaries, being worn by both the rich and the poor. Its use is widespread among different strata of society, symbolizing its universal appeal and accessibility. The fabric’s rich colors and patterns are appreciated by all, making it a symbol of cultural unity.

Symbol of Respect and Hospitality

Ajrakh is also a symbol of respect and hospitality. Gifting Ajrakh fabric is a gesture of goodwill and honor, often used to welcome guests and dignitaries. The act of presenting Ajrakh signifies deep respect and conveys a sense of warmth and hospitality.

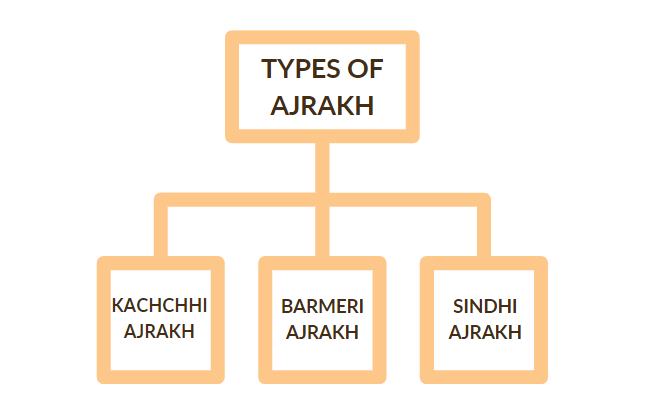

WHAT ARE THE REGIONAL VARIATIONS IN AJRAKH MAKING?

Ajrakh, the ancient craft of hand block printing, exhibits regional variations that reflect the diverse cultural and environmental influences of the areas where it is practiced. The three prominent types of Ajrakh are Kachchhi Ajrakh, Barmeri Ajrakh, and Sindhi Ajrakh, each with unique characteristics and techniques.

Kachchhi Ajrakh

Found in the Kutch (Kachchh) region of Gujarat, India, Kachchhi Ajrakh is known for its intricate patterns and multiple stages of printing and dyeing. The process involves the use of natural dyes such as indigo and madder, and it includes several resist printing techniques to create complex designs. The designs are typically geometric and symmetrical, often featuring motifs like stars, flowers, and various traditional symbols. The color palette is usually dominated by deep blues, rich reds, and blacks, achieved through the use of natural dyes. The craft is primarily practiced by the Khatri community, who have been preserving and passing down the techniques through generations.

Barmeri Ajrakh

Found in the Barmer district of Rajasthan, India, Barmeri Ajrakh is characterized by its vibrant colors and bold patterns. The printing process involves fewer stages compared to Kachchhi Ajrakh, making it slightly less intricate but more vibrant. The patterns in Barmeri Ajrakh often include floral and faunal motifs, reflecting the natural surroundings of the region. Bright reds, yellows, and greens are commonly used, along with traditional indigo and black. The use of these vibrant colors makes Barmeri Ajrakh distinctively eye-catching. Artisans in Barmer have adapted the traditional techniques to suit local tastes and resources, maintaining a balance between tradition and innovation.

Sindhi Ajrakh

Found in the Sindh region of Pakistan, Sindhi Ajrakh is renowned for its deep cultural roots and elaborate processes. The technique involves multiple stages of resist dyeing and printing, often taking several weeks to complete a single piece. The designs are typically highly detailed and intricate, featuring complex geometric patterns and traditional motifs that have been used for centuries. The color palette includes the traditional indigo and madder, with additional earthy tones such as browns and blacks. The use of natural dyes is a hallmark of Sindhi Ajrakh. The Sindhi craftsmen, often referred to as Ajrakhs, have maintained the authenticity and originality of the craft, ensuring that each piece is a reflection of their rich cultural heritage.

PROCESS OF AJRAKH MAKING

Raw Materials

· Choti Harar

· Choch Harar

· Jaggery

· Indigo

· Sugar

· Dhavdi Gond

· Manjuphal

· Dadam

· Alizar

· Sakud

· Kesua Flower

· Harar

Natural Dyes

Indigo: Derived from the indigo plant, it is used for creating blue hues.

Madder Root: Used for red colors.

Pomegranate Rind: Provides yellow and green shades.

Rusty Iron (Ferrous Sulphate): Mixed with tamarind seed powder to produce black dye.

Alizarin: Another source for red dye, derived from the madder plant.

Turmeric: Used to achieve yellow shades.

Harad (Myrobalan): Used as a mordant to fix the dyes onto the fabric.

Mordants and Fixatives

Alum: Commonly used as a mordant to fix dyes.

Myrobalan (Harad): Helps in fixing the colors onto the fabric.

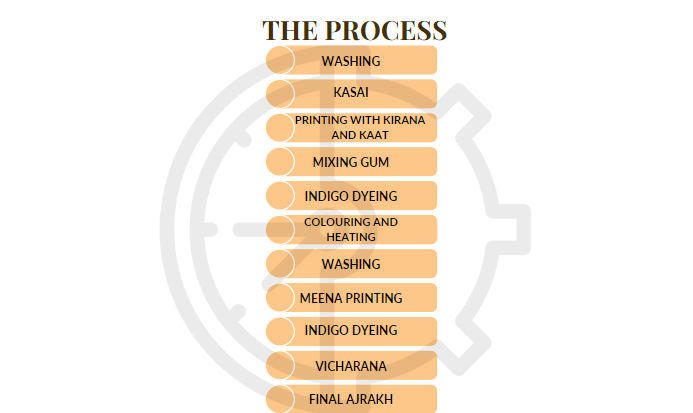

The Process

The process of making Ajrakh is a highly detailed and labor-intensive craft that involves multiple stages of preparation, dyeing, and printing. Each step is crucial to achieving the intricate designs and vibrant colors characteristic of Ajrakh textiles. Here’s an elaborate breakdown of the steps:

1. Washing (Dhulai)

The process starts with a grey-colored cloth from which smaller pieces, each measuring 5.5 square meters, are cut. These pieces are then soaked in a mixture of castor oil, soda bicarbonate, and water for up to 24 hours. Next, the soaked cloth pieces are washed by repeatedly hitting them on a large rock. These steps are continued for over three days until the cloth becomes sufficiently soft to absorb color.

2. Kasai

After the initial washing, a semi-solid mixture is prepared, containing myrrh powder, arandi oil (castor oil), sesame oil, sakud powder, and about 20 liters of water to make 90-100 balls. Each ball is added to a piece of fabric, and the cloth is soaked in this mixture. The mixture acts as a mordant, helping the fabric absorb dyes better. The fabric is then made creaseless by washing it again on a big stone. It is dried with the help of two people who pull it tightly from both ends.

3. Printing with Kirana and Kaat

The Kirana mixture is made from Babul gum, limestone powder, mustard oil, water, Multani Mitti, and fresh cow dung. This mixture is left to sit for a week. After this period, it is sieved through a fine cloth, and then it is used to print the design outlines on the cloth pieces.

Kaat is essentially a mixture of iron, jaggery, flour, bajra, and water, left to rot until it turns black. This mixture is then used to develop the outline of the drawing. For finer designs, Kaat stamps are employed.

4. Mixing Gum

Another mixture used for printing cloth contains fatkadi (alum) and tamarind seed flour. Workers create a pulp by mixing ghadvi gum, lal kashish, Multani Mitti, samunda gum from Kumbhat, and water, using their feet to combine the ingredients. Since the printing done with this mixture is wet, it must be dried by sprinkling cow dung powder over it.

5. Indigo Dyeing

The fabric is then submerged in an indigo dye vat. Indigo is a natural dye extracted from the indigo plant. The resist areas remain unaffected by the dye, while the exposed areas turn a deep blue. This step requires careful handling to ensure even dyeing. After dyeing with indigo, the cloth pieces begin looking light green after being washed thoroughly.

6. Colouring (Ghaana) and Heating (Tapaai)

This step involves boiling the cloth pieces in a mixture of Dhawdi flowers, Sakud oil, Alijer, and water. Once the cloth is properly colored, it is washed again. To secure the colors, the cloth pieces are soaked overnight in a mixture made from caramel, dung, and soda bicarbonate.

7. Washing (Dhulai)

Then, the fabric undergoes another round of washing before offering for sale. These are sold as one-side dyed Ajrakh cloth.

8. Meena Printing (Chapi)

In this step, the printing is done using Alijer and Hansa. This step adds more color layers to the design.

9. Indigo Dyeing (Gehra Karna)

Indigo Ajrakh, known for its darker color, undergoes a special process to achieve its deep hues. After the initial dyeing, the cloth is dipped in an indigo vat. It is then left idle for 2-3 days to allow the dye to fully penetrate and develop a richer color. Following this period, the cloth is washed thoroughly to remove any excess dye and to set the color. This additional indigo dipping and resting process results in the characteristic deep blue of Indigo Ajrakh.

10. Vicharana

The next step involves putting the cloth pieces in another mixture of Fitkaris, soda bicarbonate, turmeric and water. It is then left to dry overnight.

11. Final Ajrakh

The fabric is now washed for the last time with turmeric and pomegranate water or fitkaris. For a shining effect, water is sprinkled 4-5 times on them. The procedure is now complete, showcasing the intricate and vibrant patterns that are characteristic of Ajrakh printing. The final product is a beautiful and durable textile with complex designs and rich colors, reflecting the skilled craftsmanship involved in its creation.

Each step in the Ajrakh-making process requires precision and expertise, contributing to the unique beauty and high quality of the finished textile. The use of natural dyes and traditional techniques also ensures that each piece of Ajrakh is unique and eco-friendly.

Information taken from Chaap Sitara

Recommended

Wholesale / B2b Kathputli Puppets From Ahemdabad

Dec 16, 2024